- 0755-21675213

- acdrive@micno.com.cn

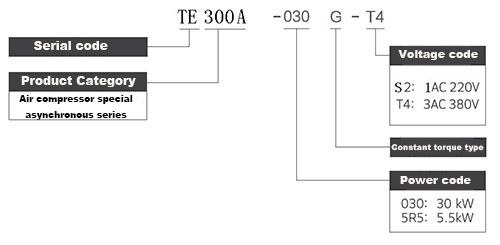

Comparado com o tradicional sistema de controlo de Velocidade variável do compressor de ar de frequência variável, o compressor de ar Da série TE300A, o inversor assíncrono especial construído com um algoritmo de controlo inteligente de super peritos para alcançar UMA combinação dinâmica Da pressão de fornecimento de ar e Da Velocidade do compressor de ar.

More Energy Efficient

Automaticamente otimizar o consumo de Energia de saída com base no valor de pressão do compressor de ar.Reduzir a potência real de saída do motor para alcançar a poupança de Energia

Resposta Rápida

Ajustar rapidamente a resposta Quando a flutuação do consumo de gás é relativamente Grande

Mais estável

EM comparação com o controle de interruptor de limite superior e inferior Da operação de frequência de energia,A pressão de fornecimento de ar é Mais estável.

Produção contínua

Reiniciação automática de falhas e função de reposição do sistema garantem a continuidade do sistema e não afetam a produção.

Item | Technical Indicators | Description |

Input | Input voltage (V) | 3AC 380V±15% |

Input frequency (Hz) | 47~63Hz | |

Output | Output voltage (V) | 0~rated input voltage |

Output frequency (Hz) | V/f control:0~3000Hz Sensorless vector control:0~300Hz | |

Control Features | Control mode | V/f control Sensorless vector control Torque control |

Operation command mode | Keypad control Terminal control Serial communication control | |

Frequency setting mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined & switched in various modes. | |

Overload capacity | G model: 150% 60s, 180% 10s, 200% 3s | |

Starting torque | 0.5Hz/150% (SVC),1Hz/150% (V/f) | |

Speed adjustment range | 1:100 (SVC),1:50(V/f) | |

Speed control precision | ±0.5%(SVC) | |

Carrier frequency | 1.0--16.0kHz, automatically adjusted according to temperature and load characteristics | |

Frequency accuracy | Digital setting: 0.01Hz Analog setting: maximum frequency * 0.05% | |

Torque boost | Automatically torque boost; manually torque boost: 0.1%~30.0% | |

V/f curve | Three types: linear, multiple point and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | |

Acceleration/deceleration mode | Straight line/S curve; four kinds of acceleration/deceleration time, range: 0.1s~3600.0s | |

DC braking | DC braking when starting and stopping DC braking frequency: 0.0Hz~maximum frequency, braking time: 0.0s~100.0s | |

Jog operation | Jog operation frequency: 0.0Hz~maximum frequency Jog acceleration/deceleration time: 0.1s~3600.0s | |

Simple PLC & multi-step speed operation | It can realize a maximum of 16 segments speed running via the built-in PLC or control terminal. | |

Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | |

Automatic voltage regulation | Keep output voltage constant automatically when input voltage fluctuating | |

Control Function | Common DC bus | Common DC bus for several inverters, energy balanced automatically |

Torque control | Torque control without PG | |

Torque limit | “Rooter” characteristics, limit the torque automatically and prevent frequent over-current tripping during the running process | |

Wobble frequency control | Multiple triangular-wave frequency control, special for textile | |

Timing/length/counting control | Timing/length/counting control function | |

Over-voltage & over-current stall control | Limit current & voltage automatically during the running process, prevent frequent over-current & over-voltage tripping | |

Fault protection function | Up to 30 fault protections including over-current, over-voltage, under-voltage, overheating, default phase, overload, shortcut, etc., can record the detailed running status during failure & has fault automatic reset function | |

Input/output terminals | Input terminals | Programmable DI: 2 on-off inputs 2 programmable AI: A1: 0~10V or 0/4~20mA |

Output terminals | 1 relay output 1 analog output: 0/4~20mA or 0~10V | |

Communication terminals | Offer RS485 communication interface, support MODBUS-RTU communication protocol | |

Human machine interface | LED display | Display frequency setting, output frequency, output voltage, output current, etc. |

Multifunction key | QUICK/JOG key, can be used as multifunction key | |

Environment | Ambient temperature | -10℃~40℃, derated 4% when the temperature rise by every 1℃ (40℃~50℃). |

Humidity | 90%RH or less (non-condensing) | |

Altitude | ≤1000M: output rated power, >1000M: output derated | |

Storage temperature | -20℃~60℃ | |

Storage environment | Indoor, no direct sunlight, dust, corrosive gases, flammable gases, oil mist, steam, dripping, salt, vibration |

model | Adapter motor | Rated input current(A) | Rated output current(A) | |

kW | HP | |||

Three-phase 380V | ||||

TE300A-004G-T4 | 4.0 | 5 | 10 | 9 |

TE300A-5R5G-T4 | 5.5 | 7.5 | 15 | 13 |

TE300A-7R5G-T4 | 7.5 | 10 | 20 | 17 |

TE300A-011G-T4 | 11 | 15 | 26 | 25 |

TE300A-015G-T4 | 15 | 20 | 35 | 32 |

TE300A-018G-T4 | 18.5 | 25 | 38 | 37 |

TE300A-022G-T4 | 22 | 30 | 46 | 45 |

TE300A-030G-T4 | 30 | 40 | 62 | 60 |

TE300A-037G-T4 | 37 | 50 | 76 | 75 |

TE300A-045G-T4 | 45 | 60 | 92 | 90 |

TE300A-055G-T4 | 55 | 75 | 112 | 110 |

TE300A-075G-T4 | 75 | 100 | 157 | 150 |

TE300A-090G-T4 | 90 | 125 | 180 | 176 |

TE300A-110G-T4 | 110 | 150 | 214 | 210 |

TE300A-132G-T4 | 132 | 175 | 256 | 253 |

TE300A-160G-T4 | 160 | 210 | 307 | 304 |

TE300A-185G-T4 | 185 | 250 | 350 | 340 |

TE300A-200G-T4 | 200 | 260 | 385 | 377 |

TE300A-220G-T4 | 220 | 300 | 430 | 423 |

LEAVE_MSG